Few things, if any, make more difference in a distributor’s business model than efficient inventory management.

The right inventory drives your sales. The right inventory to sales ratio makes you profitable (not taking anything else into account). Too much inventory – you lose money. Too little inventory you lose customers and money. So theoretically, ensuring you always have the right amount of inventory is a major key in profitability!

So how do you manage your inventory?

We are familiar with inventory management methods dating back to WW2 logistics such as re-order points, safety stock and so forth all the way to MRP, Gordon Graham Principles, JIT, Lean Methods and more. All of these methods have one purpose in mind – manage your inventory to sales ratio for maximum revenue.

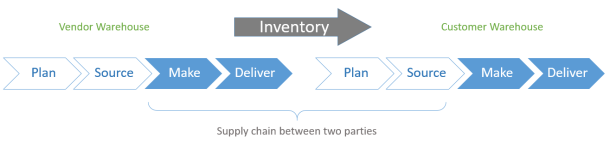

Not so long ago, everyone started working together – collaborate – to keep inventory stock at a minimum but at maximum customer satisfaction and availability. So along comes Consignment Inventory and Vendor Managed Inventory.

Consignment Inventory (CI): The inventory I (distributor) keep at my customer site(s)

Vendor Managed Inventory (VMI): The inventory my vendor keeps at my (distributor) site(s)

Advantages of Utilizing CI and/or VMI

CI – I (distributor) can increase customer satisfaction and reduce costs by agreeing to place inventory in a customer location at no cost to the customer until they use it. There are major advantages for both the vendor and the customer.

- What better way to meet JIT (Just in Time) delivery requirements than by having my inventory on site at the customer location?

- Having inventory on site and available to my customer as they need it – no chance he will order from a competitor.

- The inventory is still owned by me and – after discussing with my customer – I can still move as necessary.

- I have total visibility into usage and can avoid returns due to lack of sales as I will be managing this inventory location as one of my own.

- As part of agreement, ensure that the customer reviews and updates forecasts regularly for more accurate requirements.

- Agree to inventory cycle counts at regular intervals – our customer can perform them or I may send my sales person – direct regular access to my customer’s procurement department.

- Negotiate better margins with customers for 100% inventory availability.

- Negotiate with your vendor to ship replenishments directly to the customer location and save on transportation costs, receiving and stocking costs and pick, pack ship costs to send the inventory to your customer – if the quantities warrant this process. This process alone can make a huge impact on margins for you or a combination of price reduction to your customer and still positive impact your margins.

VMI – I (distributor) can increase customer satisfaction and reduce costs by agreeing to let my vendor place inventory at my location at no cost to me until I use it. There are major advantages for both myself and my vendor that can lead to positive results in my margins and inventory carrying costs and turns for me (distributor).

- Since the inventory is not owned by me – not invoiced yet – until I use it then the inventory carrying costs are not affecting my profitability or are reduced.

- I (distributor) do not reflect this inventory as mine my inventory turn ratio is affected positively.

- Immediate availability will have a positive impact on my lead times.

- Immediate availability will improve my customer satisfaction.

- I can negotiate a better price with my vendor as I am managing the inventory and will commit to certain level of guaranteed usage.

Why is this becoming more prevalent?

It’s easy. The process itself is logical and simple to understand. Execution is often another matter altogether. Taking advantage of CI and/or VMI requires having software in place that is capable of automating much of the process.

- CI – Customer shows usage, distributor system (my system) accepts the usage, creates a SO, created the pick/pack/ship documents to support the shipment and update the distributor inventory, creates an invoice to transfer ownership to customer and request payment, planning system plans to replenish the customer site based on forecast and consumption. Customer now owns the inventory.

- VMI – Distributor advises vendor of usage so vendor forwards invoice. The distributor system (my system) creates a purchase order, a receipt is automatically created and executed on, the distributor (my) system is updated, vendor invoice is now ready to be accepted and paid. The distributor system recognizes the inventory for planning, allocation and consumption. Ownership is now mine.

AXIO for Distribution Supports Both CI and VMI Inventory Management

AXIO for Distribution provides a complete distribution solution that enables and automates standard processes to support both VMI and CI. These processes have training and implementation documentation to help you roll out both or either one of these inventory management methods.

Of course, AXIO for Distribution is much more than inventory management. It is an end-to-end advanced supply chain management software for both small and large distributors. We’ve extended the powerful capabilities of Microsoft Dynamics AX to include industry-specific functionalities that cover all the important processes a modern distributor needs: sales and operations planning, demand planning, revenue management, order management, inventory management, business intelligence, procurement management and more.

Built by industry experts, AXIO for Distribution goes beyond traditional enterprise resource planning (ERP) software to tackle the complex needs of today’s distributors and enable business gains.

Please reach out if you would like to learn more about how AXIO for Dynamics AX and Dynamics 365 can help your distribution business operate more efficiently.

Dominic Telaro CFPIM, CIRM

Vice President Industry Solutions, SBS Group

Dominic Telaro brings over 35 years of Manufacturing, Distribution, Software and

Consulting experience. Half of his professional career has been in Manufacturing and Distribution from shop floor and warehousing positions to management. During this time he implemented ERP, DRP and Logistics solutions as internal Project Leader. The second half of his career has been in consulting, product management, product development and both consulting and software sales. He has held positions as VP Of Industry Solutions, VP of Product Development, VP of Sales and Marketing and Global Practice Leader for companies like IBIS Inc., IBM, Janis Group, Metamor, Marcam Corp. and more. Presently he is responsible for Industry Product Vision for multiple ERP solutions at SBS Group USA.

APICS Fellow and Certified in Integrated Resource Management, Instructor at Universite de Montreal, Vanier College and Granby CEGEP for APICS certification; Lead instructor for internal APICS training at Bell Helicopter, Avon, Le Groupe Hamelin